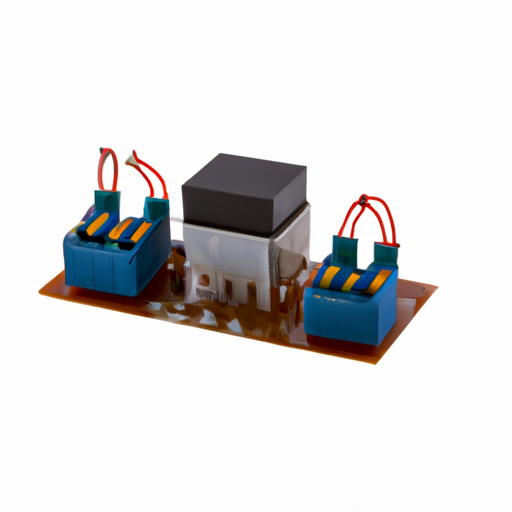

Switched-mode power supplies (SMPS) are widely used in various electronic devices to efficiently convert electrical power from one form to another. One of the key components of an SMPS is the transformer, which plays a crucial role in the power conversion process. In this article, we will explore the components and modules that make up an SMPS transformer and discuss their functions in detail.

1. Primary winding: The primary winding is the input side of the transformer, where the input voltage is applied. This winding is typically connected to the input power source and carries the alternating current (AC) input signal. The primary winding is responsible for transferring the input power to the secondary winding through the process of electromagnetic induction.

2. Secondary winding: The secondary winding is the output side of the transformer, where the output voltage is generated. This winding is connected to the load or the output circuit of the power supply and carries the converted AC or direct current (DC) output signal. The secondary winding is responsible for stepping up or stepping down the voltage level as required by the application.

3. Core: The core of the transformer is a magnetic material that provides a path for the magnetic flux generated by the primary and secondary windings. The core material is chosen based on its magnetic properties, such as permeability and saturation level, to ensure efficient power transfer and minimal losses. Common core materials used in SMPS transformers include ferrite, iron, and laminated steel.

4. Bobbin: The bobbin is a plastic or ceramic structure that holds the primary and secondary windings in place and provides insulation between the windings and the core. The bobbin also helps in the assembly and mounting of the transformer components, ensuring proper alignment and spacing of the windings. The bobbin design is critical for maintaining the electrical and mechanical integrity of the transformer.

5. Insulation: Insulation materials are used to provide electrical isolation between the primary and secondary windings, as well as between the windings and the core. Insulation helps prevent short circuits and ensures the safety and reliability of the transformer. Common insulation materials used in SMPS transformers include enamel-coated wire, polyester film, and epoxy resin.

6. Winding configuration: The winding configuration of the transformer determines the voltage ratio between the primary and secondary windings. The turns ratio of the windings is calculated based on the desired output voltage and current requirements of the power supply. The winding configuration also affects the efficiency and regulation of the transformer, as well as its ability to handle different load conditions.

7. Shielding: Shielding is used to reduce electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues in the power supply. Shielding materials such as copper foil or conductive paint are applied to the transformer components to contain the electromagnetic fields and prevent interference with other electronic devices. Proper shielding is essential for ensuring the proper operation of the power supply in noisy environments.

8. Thermal management: Thermal management is crucial for maintaining the temperature of the transformer within safe operating limits. Heat generated during the power conversion process can affect the performance and reliability of the transformer. Thermal management techniques such as heat sinks, thermal pads, and cooling fans are used to dissipate heat and prevent overheating of the transformer components.

In conclusion, the SMPS transformer is a critical component of switched-mode power supplies that plays a key role in converting electrical power efficiently and reliably. By understanding the components and modules that make up an SMPS transformer, engineers and designers can optimize the performance and efficiency of power supplies for a wide range of applications. Proper design, selection, and integration of transformer components are essential for achieving high-quality power conversion and ensuring the safety and reliability of electronic devices.

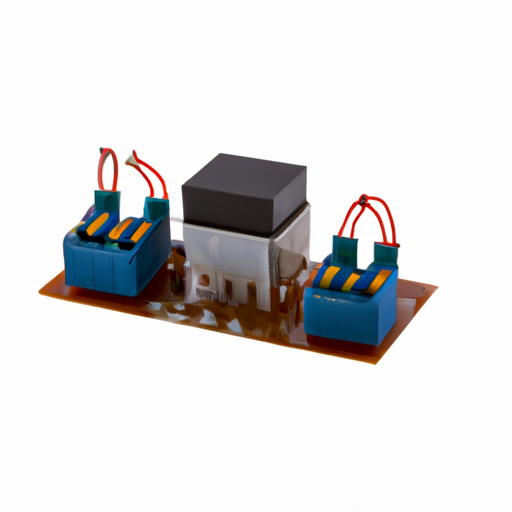

Switched-mode power supplies (SMPS) are widely used in various electronic devices to efficiently convert electrical power from one form to another. One of the key components of an SMPS is the transformer, which plays a crucial role in the power conversion process. In this article, we will explore the components and modules that make up an SMPS transformer and discuss their functions in detail.

1. Primary winding: The primary winding is the input side of the transformer, where the input voltage is applied. This winding is typically connected to the input power source and carries the alternating current (AC) input signal. The primary winding is responsible for transferring the input power to the secondary winding through the process of electromagnetic induction.

2. Secondary winding: The secondary winding is the output side of the transformer, where the output voltage is generated. This winding is connected to the load or the output circuit of the power supply and carries the converted AC or direct current (DC) output signal. The secondary winding is responsible for stepping up or stepping down the voltage level as required by the application.

3. Core: The core of the transformer is a magnetic material that provides a path for the magnetic flux generated by the primary and secondary windings. The core material is chosen based on its magnetic properties, such as permeability and saturation level, to ensure efficient power transfer and minimal losses. Common core materials used in SMPS transformers include ferrite, iron, and laminated steel.

4. Bobbin: The bobbin is a plastic or ceramic structure that holds the primary and secondary windings in place and provides insulation between the windings and the core. The bobbin also helps in the assembly and mounting of the transformer components, ensuring proper alignment and spacing of the windings. The bobbin design is critical for maintaining the electrical and mechanical integrity of the transformer.

5. Insulation: Insulation materials are used to provide electrical isolation between the primary and secondary windings, as well as between the windings and the core. Insulation helps prevent short circuits and ensures the safety and reliability of the transformer. Common insulation materials used in SMPS transformers include enamel-coated wire, polyester film, and epoxy resin.

6. Winding configuration: The winding configuration of the transformer determines the voltage ratio between the primary and secondary windings. The turns ratio of the windings is calculated based on the desired output voltage and current requirements of the power supply. The winding configuration also affects the efficiency and regulation of the transformer, as well as its ability to handle different load conditions.

7. Shielding: Shielding is used to reduce electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues in the power supply. Shielding materials such as copper foil or conductive paint are applied to the transformer components to contain the electromagnetic fields and prevent interference with other electronic devices. Proper shielding is essential for ensuring the proper operation of the power supply in noisy environments.

8. Thermal management: Thermal management is crucial for maintaining the temperature of the transformer within safe operating limits. Heat generated during the power conversion process can affect the performance and reliability of the transformer. Thermal management techniques such as heat sinks, thermal pads, and cooling fans are used to dissipate heat and prevent overheating of the transformer components.

In conclusion, the SMPS transformer is a critical component of switched-mode power supplies that plays a key role in converting electrical power efficiently and reliably. By understanding the components and modules that make up an SMPS transformer, engineers and designers can optimize the performance and efficiency of power supplies for a wide range of applications. Proper design, selection, and integration of transformer components are essential for achieving high-quality power conversion and ensuring the safety and reliability of electronic devices.