The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionIn recent years, the term "renewable energy" has become a buzzword in discussions about climate change, sustainability, and the future of our planet. But what exactly does renewable energy mean? At its core, renewable energy refers to energy derived from natural sources that are replenished at a faster rate than they are consumed. This includes solar, wind, hydro, biomass, and geothermal energy. As the world grapples with the dire consequences of climate change, the importance of transitioning to renewable energy sources has never been more critical. This article will explore the historical context of energy sources, the various types of renewable energy, the role of technology, economic implications, global perspectives, future trends, and ultimately, the path towards a sustainable future. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their ImpactFor centuries, humanity has relied heavily on fossil fuels—coal, oil, and natural gas—as the primary sources of energy. The Industrial Revolution marked a significant turning point, as the demand for energy surged, leading to an increased reliance on these non-renewable resources. 1. **Brief History of Fossil Fuel Usage** The use of fossil fuels can be traced back to ancient civilizations, but it was not until the 18th and 19th centuries that their consumption skyrocketed. The advent of steam engines, electricity, and automobiles created an insatiable demand for oil and coal, which fueled economic growth and industrialization.2. **Environmental Consequences** However, the environmental consequences of fossil fuel consumption are profound. The burning of fossil fuels releases greenhouse gases (GHGs) into the atmosphere, contributing to global warming and climate change. Additionally, fossil fuel extraction and transportation can lead to oil spills, habitat destruction, and air and water pollution, posing significant risks to ecosystems and human health. B. The Emergence of Renewable EnergyAs the negative impacts of fossil fuels became increasingly apparent, the search for alternative energy sources gained momentum. 1. **Early Uses of Renewable Energy** Renewable energy is not a new concept; ancient civilizations harnessed the power of the sun, wind, and water for various purposes. For instance, windmills were used for grinding grain, and waterwheels powered early industrial processes. 2. **Technological Advancements Leading to Modern Renewable Energy** The 20th century saw significant technological advancements that made renewable energy more viable. The development of photovoltaic cells in the 1950s marked a turning point for solar energy, while advancements in turbine technology revolutionized wind energy production. III. Types of Renewable Energy A. Solar Energy1. **How Solar Panels Work** Solar energy is harnessed through photovoltaic (PV) cells that convert sunlight into electricity. When sunlight hits the PV cells, it excites electrons, creating an electric current. This electricity can be used immediately or stored in batteries for later use.2. **Benefits and Challenges of Solar Energy** The benefits of solar energy are numerous: it is abundant, sustainable, and produces no emissions during operation. However, challenges remain, including the high initial costs of installation, the need for large areas for solar farms, and the intermittent nature of sunlight. B. Wind Energy1. **Mechanism of Wind Turbines** Wind energy is generated by converting the kinetic energy of wind into mechanical power using wind turbines. As wind blows, it turns the blades of the turbine, which spins a generator to produce electricity.2. **Advantages and Limitations of Wind Energy** Wind energy is one of the fastest-growing renewable energy sources, offering a clean and sustainable alternative to fossil fuels. However, it is not without limitations, including noise pollution, the impact on wildlife, and the need for suitable locations with consistent wind patterns. C. Hydropower1. **Overview of Hydroelectric Power Generation** Hydropower harnesses the energy of flowing water to generate electricity. Dams are often built on rivers to create reservoirs, and as water flows through turbines, it generates power.2. **Environmental Considerations** While hydropower is a reliable and efficient energy source, it can have significant environmental impacts, including habitat disruption, changes in water quality, and effects on fish populations. D. Biomass and Biofuels1. **Definition and Sources of Biomass** Biomass refers to organic materials, such as plant and animal waste, that can be used as fuel. Common sources include agricultural residues, wood, and dedicated energy crops.2. **Role of Biofuels in Energy Production** Biofuels, such as ethanol and biodiesel, are derived from biomass and can be used as alternatives to gasoline and diesel. They offer a renewable option for transportation fuels, but their production can compete with food resources and lead to deforestation. E. Geothermal Energy1. **Explanation of Geothermal Systems** Geothermal energy harnesses heat from the Earth’s interior to generate electricity or provide direct heating. This is achieved by tapping into hot water or steam reservoirs underground.2. **Potential and Challenges of Geothermal Energy** Geothermal energy is a reliable and consistent energy source, with a small land footprint. However, it is geographically limited to areas with volcanic activity or hot springs, and the initial costs of drilling can be high. IV. The Role of Technology in Renewable Energy A. Innovations in Energy StorageOne of the significant challenges of renewable energy is its intermittent nature. Innovations in energy storage, particularly battery technology, are crucial for overcoming this hurdle. Advanced batteries, such as lithium-ion and flow batteries, allow for the storage of excess energy generated during peak production times for use during periods of low generation. B. Smart Grid Technology and Its Impact on Energy DistributionSmart grid technology enhances the efficiency and reliability of energy distribution. By integrating digital technology into the electrical grid, utilities can better manage energy flow, reduce outages, and accommodate the variable nature of renewable energy sources. This technology also empowers consumers to monitor and manage their energy usage more effectively. C. The Role of Artificial Intelligence in Optimizing Energy UseArtificial intelligence (AI) is playing an increasingly important role in optimizing energy use. AI algorithms can analyze vast amounts of data to predict energy demand, optimize energy production, and improve the efficiency of renewable energy systems. This technology can lead to more effective energy management and reduced costs. V. Economic Implications of Renewable Energy A. Job Creation in the Renewable Energy SectorThe transition to renewable energy is not only beneficial for the environment but also for the economy. The renewable energy sector has proven to be a significant source of job creation. According to the International Renewable Energy Agency (IRENA), the sector employed over 11 million people globally in 2018, with numbers expected to rise as investment in renewables continues to grow. B. Cost Comparison: Renewable Energy vs. Fossil FuelsThe cost of renewable energy has decreased dramatically over the past decade, making it increasingly competitive with fossil fuels. According to the International Energy Agency (IEA), the cost of solar photovoltaic (PV) electricity has fallen by 82% since 2010, while onshore wind costs have dropped by 49%. As technology continues to advance, the cost of renewables is expected to decline further, making them the preferred choice for energy generation. C. Government Policies and Incentives Promoting Renewable EnergyGovernment policies and incentives play a crucial role in promoting the adoption of renewable energy. Many countries have implemented feed-in tariffs, tax credits, and renewable portfolio standards to encourage investment in clean energy. These policies not only stimulate economic growth but also help to reduce greenhouse gas emissions. VI. Global Perspectives on Renewable Energy Adoption A. Case Studies of Countries Leading in Renewable EnergySeveral countries have emerged as leaders in renewable energy adoption, showcasing the potential for a sustainable energy future.1. **Germany** Germany's Energiewende (energy transition) policy has positioned the country as a global leader in renewable energy. With a strong focus on solar and wind energy, Germany aims to generate 80% of its electricity from renewables by 2050.2. **Denmark** Denmark is renowned for its wind energy production, generating over 40% of its electricity from wind turbines. The country has set ambitious goals to become carbon-neutral by 2050, further solidifying its commitment to renewable energy.3. **China** China is the world's largest producer of solar panels and wind turbines, leading the way in renewable energy investment. The country has set a target to reach 20% of its energy consumption from non-fossil fuels by 2025. B. Challenges Faced by Developing Countries in Adopting Renewable EnergyWhile many developed countries are making strides in renewable energy adoption, developing countries face unique challenges. Limited access to financing, inadequate infrastructure, and political instability can hinder the transition to renewable energy. However, innovative solutions, such as off-grid solar systems, are emerging to address these challenges and provide clean energy access to underserved populations. C. International Agreements and CollaborationsInternational agreements, such as the Paris Agreement, play a vital role in promoting global cooperation on climate change and renewable energy. These agreements set targets for reducing greenhouse gas emissions and encourage countries to invest in clean energy technologies. Collaborative efforts, such as the International Solar Alliance, aim to accelerate the deployment of solar energy in developing countries. VII. Future Trends in Renewable Energy A. Predictions for Renewable Energy GrowthThe future of renewable energy looks promising, with predictions indicating continued growth in the sector. According to the IEA, renewable energy is expected to account for nearly 80% of global electricity generation by 2030. This growth will be driven by technological advancements, decreasing costs, and increasing demand for clean energy. B. Emerging TechnologiesSeveral emerging technologies have the potential to revolutionize the renewable energy landscape:1. **Floating Solar Farms** Floating solar farms, which are installed on bodies of water, offer a space-efficient solution for solar energy generation. These installations can reduce evaporation and help maintain water quality while generating clean energy.2. **Advanced Wind Turbines** Innovations in wind turbine design, such as larger blades and improved materials, are increasing the efficiency and output of wind energy. Offshore wind farms are also gaining traction, harnessing stronger and more consistent winds. C. The Role of Public Awareness and EducationPublic awareness and education are crucial for promoting renewable energy adoption. As individuals become more informed about the benefits of clean energy, they are more likely to support policies and initiatives that promote sustainability. Educational programs and community engagement can empower individuals to make informed choices about their energy consumption. VIII. ConclusionThe transition to renewable energy is not just an environmental imperative; it is an economic opportunity and a pathway towards a sustainable future. As we have explored in this article, the historical context, types of renewable energy, technological advancements, economic implications, global perspectives, and future trends all point towards a world increasingly powered by clean energy.As individuals, businesses, and governments, we all have a role to play in this transition. By supporting renewable energy initiatives, advocating for sustainable policies, and making conscious choices about energy consumption, we can contribute to a healthier planet for future generations. The vision of a sustainable future powered by renewable energy is within our reach, and it is up to us to make it a reality. IX. References1. International Renewable Energy Agency (IRENA). (2019). Renewable Energy and Jobs – Annual Review 2019.2. International Energy Agency (IEA). (2020). World Energy Outlook 2020.3. United Nations Framework Convention on Climate Change (UNFCCC). (2015). The Paris Agreement.4. European Commission. (2020). The European Green Deal.5. U.S. Department of Energy. (2021). Solar Energy Technologies Office. This comprehensive exploration of renewable energy highlights its significance in addressing climate change and fostering a sustainable future. As we move forward, the collective efforts of individuals, communities, and nations will be essential in realizing the full potential of renewable energy.

The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionAs the world grapples with the pressing challenges of climate change, the need for sustainable energy solutions has never been more critical. Renewable energy, derived from natural processes that are replenished constantly, offers a viable path toward reducing greenhouse gas emissions and fostering a sustainable future. This article delves into the evolution of renewable energy, exploring its historical context, various types, technological advancements, economic implications, global perspectives, and future trends. By understanding the journey of renewable energy, we can better appreciate its role in combating climate change and promoting a sustainable world. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their Impact 1. Brief History of Fossil Fuel UsageThe use of fossil fuels—coal, oil, and natural gas—dates back centuries, with coal being the first to gain prominence during the Industrial Revolution in the 18th century. The discovery of oil in the 19th century further revolutionized energy consumption, leading to the development of internal combustion engines and the widespread use of petroleum products. By the 20th century, fossil fuels had become the dominant source of energy worldwide, powering industries, transportation, and households. 2. Environmental ConsequencesWhile fossil fuels have fueled economic growth and technological advancement, their environmental impact has been profound. The combustion of fossil fuels releases significant amounts of carbon dioxide (CO2) and other greenhouse gases into the atmosphere, contributing to global warming and climate change. Additionally, fossil fuel extraction and transportation can lead to environmental degradation, oil spills, and air and water pollution, posing serious risks to ecosystems and human health. B. The Emergence of Renewable Energy 1. Early Uses of Renewable EnergyThe concept of harnessing renewable energy is not new. Ancient civilizations utilized wind and water power for various applications, such as sailing ships and milling grain. The use of solar energy can be traced back to the Greeks and Romans, who designed buildings to maximize sunlight exposure. However, it wasn't until the late 20th century that renewable energy began to gain traction as a viable alternative to fossil fuels. 2. Technological Advancements Leading to Modern Renewable EnergyThe oil crises of the 1970s sparked renewed interest in alternative energy sources, leading to significant investments in research and development. Technological advancements in solar panels, wind turbines, and hydroelectric systems have made renewable energy more efficient and cost-effective. Today, renewable energy is not only a viable alternative but is also becoming increasingly competitive with traditional energy sources. III. Types of Renewable Energy A. Solar Energy 1. How Solar Panels WorkSolar energy is harnessed through photovoltaic (PV) cells, which convert sunlight directly into electricity. When sunlight hits the PV cells, it excites electrons, creating an electric current. This electricity can be used immediately or stored in batteries for later use. Solar thermal systems, on the other hand, use sunlight to heat water or air for residential and commercial applications. 2. Benefits and Challenges of Solar EnergyThe benefits of solar energy are numerous. It is abundant, sustainable, and produces no emissions during operation. Solar energy can be harnessed at various scales, from small residential systems to large solar farms. However, challenges remain, including the intermittent nature of sunlight, the need for energy storage solutions, and the initial costs of installation. B. Wind Energy 1. Mechanisms of Wind TurbinesWind energy is generated by converting the kinetic energy of wind into electricity using wind turbines. As wind passes over the blades of a turbine, it causes them to spin, which drives a generator to produce electricity. Wind farms can be located onshore or offshore, with offshore wind farms often benefiting from stronger and more consistent winds. 2. Advantages and Limitations of Wind EnergyWind energy is one of the fastest-growing renewable energy sources globally. It is clean, abundant, and has a relatively low environmental impact compared to fossil fuels. However, wind energy also faces challenges, including variability in wind patterns, potential impacts on wildlife, and the need for suitable locations for wind farms. C. Hydropower 1. Overview of Hydroelectric Power GenerationHydropower is generated by harnessing the energy of flowing water, typically through dams that create reservoirs. Water released from the reservoir flows through turbines, generating electricity. Hydropower is one of the oldest and most established forms of renewable energy. 2. Environmental Considerations and SustainabilityWhile hydropower is a reliable and efficient energy source, it can have significant environmental impacts, including habitat disruption, changes in water quality, and effects on fish populations. Sustainable hydropower practices aim to minimize these impacts while maximizing energy production. D. Biomass and Biofuels 1. Definition and Types of Biomass EnergyBiomass energy is derived from organic materials, such as plant and animal waste. It can be converted into biofuels, such as ethanol and biodiesel, or used directly for heating and electricity generation. Biomass is considered renewable as long as it is sourced sustainably. 2. Role in Reducing Waste and Carbon EmissionsBiomass energy can play a crucial role in waste management by converting organic waste into usable energy. Additionally, biomass can help reduce carbon emissions when it replaces fossil fuels, as the carbon released during combustion is offset by the carbon absorbed by plants during their growth. E. Geothermal Energy 1. Explanation of Geothermal SystemsGeothermal energy harnesses heat from the Earth's interior to generate electricity or provide direct heating. Geothermal power plants use steam or hot water from underground reservoirs to drive turbines and produce electricity. Ground-source heat pumps can also be used for residential heating and cooling. 2. Potential and Challenges of Geothermal EnergyGeothermal energy is a reliable and consistent energy source, with a small land footprint and low emissions. However, its potential is geographically limited to areas with suitable geological conditions. Additionally, the initial costs of drilling and infrastructure can be high. IV. The Role of Technology in Renewable Energy A. Innovations in Energy StorageOne of the critical challenges facing renewable energy is the intermittent nature of sources like solar and wind. Innovations in energy storage technologies, particularly batteries, are essential for ensuring a stable and reliable energy supply. Advances in lithium-ion batteries, flow batteries, and other storage solutions are making it possible to store excess energy generated during peak production times for use during periods of low generation. B. Smart Grid Technology and Its Impact on Energy DistributionSmart grid technology enhances the efficiency and reliability of energy distribution systems. By integrating digital communication and automation, smart grids can optimize energy flow, reduce outages, and facilitate the integration of renewable energy sources. This technology allows for better demand response, enabling consumers to adjust their energy usage based on real-time pricing and availability. C. The Role of Artificial Intelligence in Optimizing Energy UseArtificial intelligence (AI) is playing an increasingly important role in the renewable energy sector. AI algorithms can analyze vast amounts of data to optimize energy production, predict demand, and improve energy efficiency. From predictive maintenance of renewable energy systems to smart home energy management, AI is transforming how we generate and consume energy. V. Economic Implications of Renewable Energy A. Job Creation in the Renewable Energy SectorThe transition to renewable energy is creating millions of jobs worldwide. From manufacturing solar panels and wind turbines to installation and maintenance, the renewable energy sector is a significant source of employment. According to the International Renewable Energy Agency (IRENA), the renewable energy sector employed over 11 million people globally in 2018, with numbers expected to grow as the sector expands. B. Cost Comparison: Renewable Energy vs. Fossil FuelsThe cost of renewable energy has plummeted in recent years, making it increasingly competitive with fossil fuels. According to the International Energy Agency (IEA), the cost of solar photovoltaic (PV) electricity has fallen by over 80% since 2010, while onshore wind costs have decreased by nearly 50%. As technology continues to advance and economies of scale are realized, renewable energy is expected to become even more affordable. C. Government Policies and Incentives Promoting Renewable EnergyGovernment policies and incentives play a crucial role in promoting the adoption of renewable energy. Many countries offer tax credits, grants, and subsidies to encourage investment in renewable energy projects. Additionally, renewable energy targets and mandates can drive the transition away from fossil fuels and toward a more sustainable energy future. VI. Global Perspectives on Renewable Energy Adoption A. Case Studies of Countries Leading in Renewable EnergySeveral countries are leading the way in renewable energy adoption. Germany, for example, has made significant investments in solar and wind energy, aiming to generate 80% of its electricity from renewables by 2050. Denmark is a pioneer in wind energy, with over 40% of its electricity generated from wind turbines. China has emerged as the world's largest producer of solar panels and wind turbines, investing heavily in renewable energy infrastructure. B. Challenges Faced by Developing Countries in Adopting Renewable EnergyWhile many developed countries are making strides in renewable energy adoption, developing countries face unique challenges. Limited access to financing, inadequate infrastructure, and regulatory barriers can hinder the growth of renewable energy projects. However, innovative financing models, such as pay-as-you-go solar systems, are emerging to address these challenges and promote renewable energy access in developing regions. C. International Agreements and CollaborationsInternational agreements, such as the Paris Agreement, play a vital role in fostering global cooperation on climate change and renewable energy. These agreements set targets for reducing greenhouse gas emissions and encourage countries to transition to cleaner energy sources. Collaborative initiatives, such as the International Solar Alliance, aim to promote solar energy deployment in countries with abundant sunlight. VII. Future Trends in Renewable Energy A. Predictions for Renewable Energy GrowthThe future of renewable energy looks promising, with predictions indicating continued growth in the sector. According to the IEA, renewable energy is expected to account for nearly 80% of global electricity generation by 2030. As technology advances and costs continue to decline, renewable energy will play an increasingly central role in the global energy landscape. B. Emerging Technologies and Their Potential ImpactEmerging technologies, such as floating solar farms, advanced energy storage solutions, and hydrogen fuel cells, have the potential to revolutionize the renewable energy sector. Floating solar farms can be deployed on bodies of water, reducing land use and increasing energy generation. Advanced energy storage technologies, such as solid-state batteries, promise to enhance the efficiency and reliability of energy storage systems. C. The Role of Public Awareness and Education in Promoting Renewable EnergyPublic awareness and education are crucial for driving the transition to renewable energy. As individuals and communities become more informed about the benefits of renewable energy, they are more likely to support policies and initiatives that promote its adoption. Educational programs and outreach efforts can empower individuals to make sustainable energy choices and advocate for a cleaner energy future. VIII. ConclusionThe evolution of renewable energy represents a critical shift in our approach to energy production and consumption. As we face the urgent challenges of climate change and environmental degradation, transitioning to renewable energy sources is essential for creating a sustainable future. By embracing solar, wind, hydropower, biomass, and geothermal energy, we can reduce our reliance on fossil fuels and mitigate the impacts of climate change.The journey toward a sustainable energy future requires collaboration among individuals, businesses, and governments. By investing in renewable energy technologies, supporting policies that promote clean energy, and raising awareness about the importance of sustainability, we can collectively work toward a world powered by renewable energy.As we look ahead, the vision of a sustainable future powered by renewable energy is within our reach. Together, we can create a cleaner, healthier planet for generations to come. IX. References1. International Renewable Energy Agency (IRENA). (2019). Renewable Energy and Jobs – Annual Review 2019.2. International Energy Agency (IEA). (2020). World Energy Outlook 2020.3. United Nations Framework Convention on Climate Change (UNFCCC). (2015). Paris Agreement.4. U.S. Department of Energy. (2021). Solar Energy Technologies Office.5. Global Wind Energy Council (GWEC). (2020). Global Wind Report 2020.6. World Bank. (2020). Renewable Energy for Development: A Review of the Evidence.This comprehensive exploration of renewable energy highlights its evolution, current state, and future potential. By understanding the importance of renewable energy, we can all contribute to a more sustainable and resilient world.

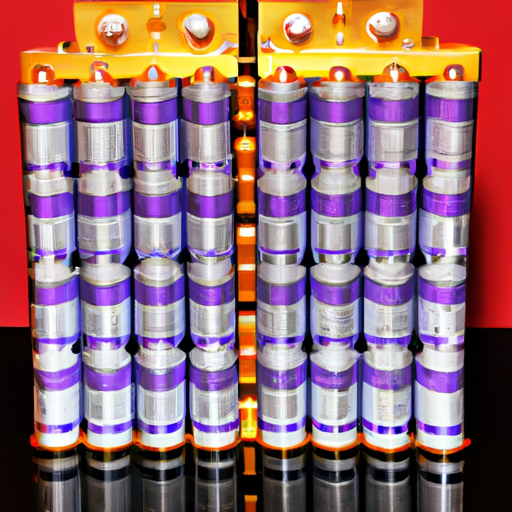

Latest Specifications for Variable Resistors Introduction1. Definition and Applications of Variable ResistorsA variable resistor, also known as a potentiometer, is an electronic component that can adjust the resistance value within a certain range. It is widely used in circuits to regulate current and voltage, control signal strength, or as part of a sensor. The applications of variable resistors include audio equipment, lighting control, temperature regulation, industrial automation, etc.2. Market Demand and Development Trends of Latest Variable ResistorsWith the continuous advancement of technology and the increasing popularity of electronic products, the market demand for high-performance variable resistors is constantly growing. Especially in the fields of smart homes, automotive electronics, and medical devices, higher requirements for the accuracy, stability, and durability of variable resistors have been put forward. In the future, with the rapid development of the Internet of Things and smart devices, the market prospects for variable resistors will be even broader.Product Overview1. Product Name and ModelThe latest variable resistor is named "High Precision Variable Resistor" with the model number "VR-2023". This product is designed for high-demand applications, with excellent performance and reliability.2. Key Features and AdvantagesHigh precision adjustment: Using advanced resistance materials and manufacturing processes to ensure the adjustment accuracy of the resistance value is ±1%.Wide range of resistance values: Resistance range from 1Ω to 1MΩ, meeting different application requirements.Excellent durability and stability: Rigorous durability tests are conducted to ensure stable performance during long-term use.Technical Specifications1. Electrical ParametersResistance range: 1Ω to 1MΩRated power: 0.5W, 1W, 2W optionalRated voltage: Maximum rated voltage is 250VTemperature coefficient: ±100ppm/°C2. Mechanical ParametersSize and weight: Diameter 20mm, weight approximately 50gMounting method: Can be fixed by screws or socket installationRotation angle: 270°3. Environmental AdaptabilityOperating temperature range: -40°C to +85°CHumidity range: 5% to 95% relative humidityProtection level: IP54Materials and Processes1. Main MaterialsResistance material: High-conductivity alloy material is used to ensure resistance stability and durability.Housing material: High-temperature resistant plastic is used, providing good insulation performance and mechanical strength.2. Manufacturing ProcessProduction process: Includes material preparation, molding, welding, testing, and packaging to ensure that each step meets quality standards.Quality control measures: Implement strict quality management systems to ensure that each product undergoes comprehensive testing before leaving the factory.Applications1. Industrial AutomationIn industrial automation, variable resistors are used to adjust motor speed, control sensor signals, etc., to improve production efficiency.2. Consumer ElectronicsIn consumer electronics such as audio equipment, televisions, variable resistors are used for volume control and signal processing to enhance user experience.3. Medical DevicesIn medical devices, variable resistors are used to precisely control the operation of equipment to ensure the safety and effectiveness of medical procedures.4. Automotive ElectronicsIn automotive electronic systems, variable resistors are used to adjust interior temperature, audio systems, etc., to enhance the driving experience.5. Other AreasIn addition, variable resistors are widely used in household appliances, lighting control, scientific research equipment, and other fields.Usage and Maintenance1. Installation PrecautionsWhen installing variable resistors, ensure that the power is disconnected and follow the installation requirements in the product manual to avoid damaging the equipment.2. User GuideDuring use, avoid exceeding the rated power and voltage to ensure the normal operation and service life of the variable resistors.3. Maintenance and Care RecommendationsRegularly check the connection status and appearance of variable resistors to ensure there is no looseness or damage. If any abnormalities are found, replace them in a timely manner.Testing and Certification1. Quality Testing StandardsProducts must undergo rigorous quality testing before leaving the factory, including electrical performance testing, mechanical performance testing, and environmental adaptability testing to ensure compliance with relevant standards.2. Certification InformationISO Certification: Products comply with ISO9001 quality management system standards.CE Mark: Complies with EU safety standards, ensuring the legality of the product in the European market.RoHS Compliance: Complies with RoHS directives, ensuring the product does not contain harmful substances.Market Prospects and Competitive Analysis1. Market Demand AnalysisWith the rapid development of smart devices and the Internet of Things, the market demand for high-performance variable resistors will continue to grow. It is expected that the market size will grow at an average annual rate of 10% in the coming years.2. Overview of CompetitorsThere are currently multiple competitors in the market, including well-known electronic component manufacturers domestically and internationally. Our product, with its high precision and excellent durability, has a strong competitive advantage.3. Market Positioning of the ProductOur high-precision variable resistors are mainly targeted at high-end markets such as industrial automation, consumer electronics, and medical devices, aiming to provide high-performance solutions.Conclusion1. Comprehensive Evaluation of the Latest Variable ResistorsThe latest variable resistors are popular products due to their high precision, wide range of resistance values, and excellent durability. They not only meet the needs of various applications but also set new benchmarks in performance and reliability.2. Outlook for Future DevelopmentWith the continuous advancement of technology and changing market demands, we will continue to focus on the technical innovation of variable resistors, striving to make breakthroughs in product performance, manufacturing processes, and application areas to provide customers with higher quality products and services.Appendix1. Related Technical Literature- "Principles and Applications of Variable Resistors"- "Selection and Design of Electronic Components"2. Contact Information and After-Sales ServiceFor more product information or after-sales service, please contact:Phone: 123-456-7890Email: support@resistor.comWebsite: www.resistor.comClosingAs an important component of electronic components, the technical development of variable resistors will directly affect the performance and reliability of electronic products. We look forward to seeing more innovations and breakthroughs in the future in terms of intelligence, miniaturization, and high performance of variable resistors.

Components and Modules of Potentiometer IntroductionA potentiometer is an instrument used to measure voltage or potential difference, widely used in various fields such as scientific research, industrial production, and medical equipment. Its basic function is to convert potential difference into readable values, helping users to make precise voltage measurements. With the advancement of technology, the design and functionality of potentiometers are constantly evolving, becoming an indispensable part of modern measurement technology. Studying the components and modules of potentiometers not only helps to understand their working principles but also provides theoretical support for their applications in various fields. I. Basic Principles of Potentiometers Working Principle of PotentiometersThe basic principle of a potentiometer is to use the voltage division characteristics to measure voltage by comparing the relationship between the voltage to be measured and a known voltage. A potentiometer usually consists of a high-impedance voltage sensor and a reference voltage source. By adjusting the reference voltage to match the voltage to be measured, the voltage value can be directly read. Measurement Methods of PotentiometersThere are mainly two measurement methods of potentiometers: direct measurement and inductive measurement. Direct measurement involves applying the voltage to be measured directly to the input terminal of the potentiometer and reading the output value, while inductive measurement involves comparing the difference between the voltage to be measured and a known voltage. Comparison of Potentiometers with Other Measuring InstrumentsCompared with other measuring instruments, potentiometers have the advantages of high accuracy and high sensitivity. For example, although a multimeter can also measure voltage, the load effect of its internal circuit may affect the measurement results. However, due to its high input impedance, a potentiometer can effectively reduce interference with the measured circuit, thereby providing more accurate measurement results. II. Main Components of Potentiometers 1. Sensor Function and Types of SensorsThe sensor is the core component of a potentiometer, responsible for converting the voltage signal into a manageable electrical signal. Common sensor types include voltage sensors, temperature sensors, and photoelectric sensors. Working Principles of Common SensorsFor example, a voltage sensor typically uses the voltage division principle to output a signal proportional to the voltage to be measured by dividing the voltage through resistors. Temperature sensors sense temperature changes through thermoelectric effects or resistance changes and convert them into voltage signals. Importance of Sensors in PotentiometersThe performance of sensors directly affects the measurement accuracy and response speed of potentiometers. Therefore, choosing the right sensor is key to designing a high-performance potentiometer. 2. Amplifier Role of AmplifiersAmplifiers in potentiometers are mainly used to enhance the weak signals output by sensors for further processing and display. They can increase the amplitude of the signal, reduce noise interference, and improve measurement accuracy. Types of AmplifiersCommon types of amplifiers include operational amplifiers, differential amplifiers, and instrumentation amplifiers. Operational amplifiers are widely used in potentiometers due to their high gain and good linearity. Application of Amplifiers in Signal ProcessingIn potentiometers, amplifiers are not only used for signal amplification but also for filtering and signal conditioning to improve measurement stability and reliability. 3. Display Module Types of Display ModulesPotentiometers' display modules usually include LCD (Liquid Crystal Display) and LED (Light Emitting Diode) types. LCDs are widely used for their low power consumption and high contrast, while LEDs are suitable for use in environments with strong light due to their high brightness and fast response. Working Principles of Display ModulesDisplay modules convert the output signal of the potentiometer into visualized numbers or graphics to help users intuitively read the measurement results. LCDs display information by changing the arrangement of liquid crystal molecules, while LEDs emit light by exciting the diodes with current to display information. Importance of Display Modules in User InterfaceDisplay modules act as a bridge between users and potentiometers, and a good display interface can improve user experience and measurement efficiency. 4. Control Unit Function of Control UnitsThe control unit is the "brain" of the potentiometer, responsible for coordinating the work of various modules, processing input signals, and controlling output results. It usually includes a microcontroller or microprocessor. Components of Control UnitsControl units typically consist of a central processing unit (CPU), memory, and input-output interfaces. The CPU executes instructions, memory stores programs and data, and input-output interfaces communicate with other modules. Role of Control Units in Data ProcessingBy processing and analyzing the output signals of sensors, control units can achieve real-time monitoring, recording, and display of data, thereby enhancing the intelligence of potentiometers. 5. Power Module Types of Power ModulesPower modules provide the necessary electrical energy for potentiometers, with common power types including batteries and adapters. Batteries are suitable for portable potentiometers, while adapters are suitable for fixed potentiometers. Stability and Reliability of Power ModulesThe stability of power modules directly affects the measurement accuracy and reliability of potentiometers. High-quality power modules can provide stable voltage and current, ensuring the normal operation of potentiometers under various working conditions. Impact of Power Modules on Potentiometer PerformanceUnstable power sources may cause fluctuations in the output signal of potentiometers, affecting measurement results. Therefore, the selection and layout of power modules should be considered during design to ensure the overall performance of potentiometers. III. Additional Modules of Potentiometers 1. Data Recording Module Function of Data Recording ModulesData recording modules are used to store measurement data of potentiometers for subsequent analysis and processing. They can save real-time data to storage media such as SD cards or memory. Data Storage MethodsData recording modules typically use non-volatile memory such as flash memory or EEPROM to ensure data is retained even after power loss. SD cards are widely used due to their large capacity and ease of replacement. Application of Data Recording Modules in ExperimentsIn scientific experiments, data recording modules can record experimental data in real-time, helping researchers analyze experimental results, compare data, and trend analysis. 2. Communication Module Types of Communication ModulesCommunication modules are used to transmit data between potentiometers and other devices, with common communication methods including Bluetooth, Wi-Fi, and wired communication. Role of Communication ModulesCommunication modules can transmit measurement data of potentiometers in real-time to computers or mobile devices, enabling users to remotely monitor and analyze data. Application of Communication Modules in Remote MonitoringIn industrial and medical fields, communication modules can achieve remote monitoring of devices, timely access to measurement data, and improve work efficiency and safety. 3. Calibration Module Importance of Calibration ModulesCalibration modules are used to ensure the measurement accuracy of potentiometers. Regular calibration of potentiometers can eliminate system errors and ensure the reliability of measurement results. Calibration Methods and StepsCalibration typically involves selecting a standard voltage source, connecting the potentiometer and the standard source, and adjusting the potentiometer output to match the standard source. Through these steps, the accuracy of the potentiometer can be ensured. Impact of Calibration Modules on Measurement AccuracyRegular calibration can effectively improve the measurement accuracy of potentiometers and ensure their reliability in various application scenarios. IV. Design and Integration of Potentiometers 1. System Integration Integration Methods of Various ModulesThe design of potentiometers requires effective integration of sensors, amplifiers, display modules, control units, and power modules. Circuit board design is commonly used to connect various modules through circuits. Challenges and Solutions in System IntegrationDuring system integration, issues such as signal interference, high power consumption, and large size may arise. These problems can be effectively addressed by optimizing circuit design, selecting appropriate components, and improving layout. Advantages of Integrated PotentiometersIntegrated design can improve the reliability, reduce costs, and facilitate maintenance and upgrades of potentiometers. 2. Design Considerations Key Factors in Potentiometer

The Main Application Directions of Coils IntroductionA coil is a circular structure made of a conductor, usually used to generate a magnetic field or induce current. Its basic principle is based on Faraday's law of electromagnetic induction, which states that when a conductor moves in a magnetic field or when the magnetic field changes, an electromotive force is induced in the conductor. Coils play a crucial role in modern technology and are widely used in various fields such as electronic devices, communication technology, medical equipment, industrial automation, energy, and environmental protection. This article will delve into the main application directions of coils and their importance in various fields. 1. Applications in Electronic Devices 1. InductorsInductors are components manufactured using the electromagnetic induction principle of coils, mainly used for storing electrical energy and limiting current changes. The working principle of inductors is that when current passes through the coil, a magnetic field is generated around it, and the change in the magnetic field induces an electromotive force in the conductor, thereby affecting the change in current.Inductors are widely used in filters and oscillators. Filters use the characteristics of inductors to select specific frequencies of signals, block other frequencies, and achieve clear signal transmission. Oscillators use a combination of inductors and capacitors to generate stable frequency signals, widely used in radios, televisions, and other electronic devices. 2. TransformersTransformers are electrical devices composed of two or more coils, mainly used for voltage conversion. Their basic structure includes primary coils and secondary coils. When current passes through the primary coil, a magnetic field is generated around it, and this magnetic field induces an electromotive force in the secondary coil, thereby achieving voltage increase or decrease.Transformers play an important role in power transmission, effectively converting high-voltage currents into low-voltage currents, reducing energy loss, and ensuring the safe transmission of electricity. The widespread use of transformers enables power systems to operate efficiently and stably. 3. Electric Motors and GeneratorsCoils play a core role in electric motors and generators. Electric motors interact with external magnetic fields by generating a magnetic field in the coil when current flows through it, driving the rotor to rotate and converting mechanical energy. Electric motors are widely used in household appliances, industrial equipment, and transportation vehicles.Generators convert mechanical energy into electrical energy. The working principle is to cut magnetic lines of force by rotating the coil in a magnetic field, generating an electromotive force. Generators are used in hydropower, wind power, thermal power generation, and are an important part of modern power systems. 2. Applications in Communication Technology 1. Wireless CommunicationIn wireless communication, coils are widely used in antenna design. The working principle of an antenna is to transmit and receive signals using electromagnetic waves generated by current in a conductor. The shape and size of the coil directly affect the performance of the antenna, and a well-designed coil can improve signal transmission efficiency and reception sensitivity.The design of tuning circuits also relies on coils. Tuning circuits adjust the inductance value of the coil to select specific frequency signals, enabling signal reception and amplification. This technology is widely used in wireless radios, televisions, and mobile communications. 2. Sensor TechnologyCoils also play an important role in sensor technology, especially in magnetic field sensors. Magnetic field sensors utilize the electromagnetic induction principle of coils to sense changes in the surrounding magnetic field and convert them into electrical signals. Common applications include wheel speed sensors in cars and electronic compasses.In addition, coils are also used in other types of sensors, such as position sensors and flow sensors. These sensors have important applications in industrial automation, smart homes, and medical equipment. 3. Applications in Medical Equipment 1. Magnetic Resonance Imaging (MRI)Magnetic Resonance Imaging (MRI) is a medical technology that uses strong magnetic fields and radio waves for imaging. Coils play a crucial role in MRI, mainly used for generating and receiving radio signals. The coils in MRI equipment can generate a uniform magnetic field and produce signals in the patient's body, achieving high-resolution imaging.The basic principle of MRI is to utilize the behavior of hydrogen atoms in a magnetic field, receive signals through coils, process them, and generate images. The design and performance of coils directly affect the quality and accuracy of imaging. 2. Biomedical Signal MonitoringCoils are also widely used in biomedical signal monitoring, especially in electrocardiograms (ECG) and electroencephalograms (EEG). Coils can sense the electrical activity of the heart and brain and convert it into visual signals. These signals are crucial for doctors to diagnose and treat diseases.The sensitivity and accuracy of coils are key factors affecting monitoring results. With technological advancements, the performance of coils continues to improve, enhancing the accuracy and reliability of biomedical signal monitoring. 4. Applications in Industry and Automation 1. Relays and ContactorsIn electrical control, coils are widely used in relays and contactors. Relays are devices that control circuits using electromagnetic principles. When the coil is energized, a magnetic field is generated, attracting the contacts to close or open, thereby controlling the circuit.The working principle of relays is simple yet effective, widely used in automation control systems such as household appliances, industrial equipment, and traffic signal control. Contactors are devices used to control high-power circuits, where the role of coils is equally indispensable. 2. Automation EquipmentCoils are increasingly being used in automation equipment. In drive systems, coils are used to control the start, stop, and speed adjustment of motors, ensuring the efficient operation of equipment. In robotics, coils are used to control sensors and actuators, enabling robots to perform complex actions and tasks.With the continuous development of industrial automation, the application of coils will become more widespread, driving the progress of various industries towards intelligence. 5. Applications in Energy and Environmental Protection 1. Wireless Charging TechnologyWireless charging technology is a rapidly developing emerging technology, where coils play a key role. The basic principle of wireless charging is to transfer electrical energy from the charger to the device through electromagnetic induction. The coils in the charger and the device interact, generating current and enabling charging.The design and optimization of coils are crucial for the efficiency and safety of wireless charging. With the continuous maturity of wireless charging technology, it will be more widely used in smartphones, electric vehicles, and other portable devices in the future. 2. Renewable EnergyCoils also play an important role in the field of renewable energy. In wind and solar power generation, coils are used in the design of generators to convert mechanical energy into electrical energy. Additionally, coils are used in energy storage systems such as batteries and supercapacitors to improve energy utilization efficiency.With the global emphasis on renewable energy, the application of coils in this field will continue to expand, driving the process of sustainable development. 6. Future Development Trends 1. New Materials and TechnologiesIn the future, the application of coils will benefit from the development of new materials and technologies. The emergence of superconducting materials reduces the resistance of coils, allowing them to operate at higher frequencies and currents, improving their performance. Additionally, the application of nanotechnology will make coils smaller in size and stronger in performance, promoting miniaturization and intelligence. 2. Intelligence and AutomationWith the proliferation of smart devices, the trend of using coils in intelligence and automation is becoming more apparent. In the future, coils will not only be passive components but will be integrated with intelligent systems to achieve self-regulation and optimization. The development of coil technology will drive progress in smart homes, intelligent transportation, and smart manufacturing. ConclusionAs an important electrical component, coils play an indispensable role in various fields. From electronic devices to communication technology, from medical equipment to industrial automation, and from energy to environmental protection, the application of coils is ubiquitous. With the continuous advancement of technology, the performance and application scope of coils will continue to expand, and future coil technology will bring more convenience and innovation to human life and production. We look forward to the future development and application of coils, contributing more to technological progress and social development.

Precautions for Inductor Product Training IntroductionIn modern electronics, inductors are important passive components widely used in power management, signal processing, and filtering. The performance of inductors directly affects the stability and efficiency of circuits, so understanding the basic knowledge and application skills of inductors is crucial for professionals in the electronics industry. This article will discuss the precautions for inductor product training to help trainers and trainees better grasp the relevant knowledge of inductors.Part One: Basics of Inductors1.1 Definition of InductorsAn inductor is a component that can store electrical energy, and its operation is based on electromagnetic induction. When current passes through an inductor, a magnetic field is generated around it, and the change in the magnetic field induces an electromotive force inside the inductor, thereby affecting the change in current. The main functions of inductors include energy storage, filtering, and impedance matching.1.2 Classification of InductorsInductors can be classified according to their structure and function, mainly into fixed inductors and variable inductors. The inductance value of fixed inductors is constant and suitable for most applications; while variable inductors can adjust the inductance value as needed, commonly used in tuning circuits and frequency selection.Different types of inductors also have different application scenarios. For example, ferrite inductors are commonly used in high-frequency circuits, while air core inductors are suitable for low-frequency circuits. Understanding these classifications and application scenarios helps in selecting the appropriate inductors for practical work.1.3 Basic Parameters of InductorsThe basic parameters of inductors include inductance value, DC resistance, rated current, etc. The inductance value is one of the most important parameters of an inductor, usually measured in henries (H). The DC resistance affects the energy loss of the inductor, while the rated current is the maximum current the inductor can withstand under normal operating conditions.During training, trainees need to learn how to measure and evaluate the performance of inductors. Commonly used measurement tools include LCR meters and oscilloscopes, through which the various parameters of the inductor can be obtained and performance evaluated.Part Two: Training Preparation2.1 Establish Training ObjectivesBefore conducting inductor product training, it is important to establish the training objectives. The different audience groups will directly affect the depth and breadth of the training content. For example, for beginners, the training content can focus on explaining the basics; while for experienced engineers, it can delve into the applications and design techniques of inductors.Setting specific training objectives helps trainers maintain direction in content design and implementation, ensuring the effectiveness of the training.2.2 Select Appropriate Training MaterialsChoosing the right training materials is key to successful training. Reference books, literature, and online resources can be consulted to ensure the authority and practicality of the selected materials. In addition, real-life case studies and application examples can help trainees better understand the connection between theoretical knowledge and practical applications.When preparing training materials, trainers should also consider the learning styles of trainees and choose a variety of material forms, such as videos, charts, and interactive exercises, to enhance trainees' interest in learning.2.3 Preparation of Training EnvironmentA good training environment can enhance the effectiveness of learning. Before training, trainers need to prepare the necessary equipment and tools, such as projectors, whiteboards, and experimental equipment. Safety precautions should also not be overlooked to ensure the safety of trainees during the training process.Part Three: Training Content Design3.1 Explanation of Theoretical KnowledgeIn the theoretical knowledge explanation part of the training, trainers should systematically introduce the basic principles of inductors and related circuit theory. Using illustrations and animations can help trainees understand the working principles of inductors more intuitively.Furthermore, trainers can use practical application examples to explain the role and impact of inductors in different circuits, enhancing trainees' practical application abilities.3.2 Practical OperationLearning theoretical knowledge cannot be separated from practical operation. In the practical session, trainers can arrange for trainees to install and debug inductors to help them master practical operation skills. Additionally, training on troubleshooting and maintenance techniques is essential; trainees need to understand the causes of common faults and their solutions to improve their independent work capabilities.3.3 Interactive SessionsTo increase participation in training, trainers should include interactive sessions such as questioning and answering, group discussions, and case studies. Through interaction, trainees can share their experiences and insights, promoting learning and exchange among each other.Part Four: Training Implementation4.1 Time Management for TrainingProper time management is key to successful training. Trainers need to schedule training time according to the complexity of the training content, ensuring that each section has enough time for explanation and discussion. At the same time, controlling the time for each section to avoid inadequate time affecting the training effectiveness.4.2 Role of TrainersTrainers play an important role in training, requiring solid professional knowledge as well as good communication skills and teaching techniques. Through vivid explanations and rich case studies, trainers can stimulate trainees' interest in learning, creating a positive learning atmosphere.4.3 Trainee EngagementEncouraging trainees to ask questions and share is an important way to enhance learning effectiveness. Trainers can promote interaction among trainees through discussion topics, group activities, etc., enhancing the initiative and enthusiasm for learning.Part Five: Training Evaluation and Feedback5.1 Evaluation of Training EffectivenessAfter the training, evaluating the effectiveness of the training is essential. Trainers can assess trainees' mastery of the training content through questionnaires, tests, and group discussions. Collecting feedback from trainees to understand their views on the training content and format is important for future training reference.5.2 Continuous ImprovementBased on trainees' feedback, trainers should adjust the training content in a timely manner to ensure it stays in line with industry developments and technological advancements. Additionally, regularly updating training materials, adding new cases and application examples, helps improve the practicality and forward-looking nature of the training.ConclusionInductors, as indispensable components in electronic circuits, are crucial for training. Through systematic training, trainees can not only master the basic knowledge of inductors but also improve their practical operation skills and troubleshooting techniques. Encouraging trainees to continue learning and practicing will help them continuously grow and progress in the electronics industry.AppendixReferences and Resource Links1. "Inductor Basics and Applications" - Electronic Industry Press2. Online Resources: IEEE Xplore, ScienceDirect3. Real Case Studies: Technical documents from major electronics manufacturersFrequently Asked Questions**Q1: What are the selection criteria for inductors?**A1: When selecting inductors, factors such as inductance value, DC resistance, rated current, frequency characteristics, etc., should be considered.**Q2: How to measure the inductance value of an inductor?**A2: An LCR meter can be used for measurement, ensuring testing is done at the appropriate frequency.**Q3: What is the main function of an inductor in a circuit?**A3: Inductors are mainly used for energy storage, filtering, impedance matching, etc., to help improve circuit performance.Through the above content, it is hoped to provide comprehensive guidance for inductor product training, helping trainers and trainees better understand and apply the relevant knowledge of inductors.

Guide to Selecting Key Words for Spot Unclassified Products IntroductionIn the world of digital marketing, the selection of keywords is crucial. It not only affects the search engine ranking of a website but also directly impacts the acquisition of potential customers. Spot unclassified keywords, as a special type of keyword, are often overlooked, but their potential value should not be underestimated. This article will explore how to effectively select spot unclassified keywords to help businesses stand out in a competitive market.Part One: Basic Concepts of Keywords1. Definition of KeywordsKeywords are the words or phrases that users input into search engines, serving as the bridge between user needs and website content. In Search Engine Optimization (SEO), the selection and use of keywords directly impact the visibility and traffic of a website. Through proper keyword placement, businesses can attract more target audiences, increase website traffic, and conversion rates.2. Characteristics of Spot Unclassified KeywordsSpot unclassified keywords refer to keywords that have not been widely used or classified. These keywords typically have lower competitiveness and higher potential traffic, making them suitable for businesses to focus on in specific areas. Compared to traditional popular keywords, spot unclassified keywords often provide more targeted traffic for businesses, helping them establish a presence in specific markets.Part Two: Steps to Select Spot Unclassified Keywords1. Market ResearchBefore selecting keywords, conducting market research is essential. Understanding the needs and behaviors of target audiences, analyzing competitors' keyword strategies, can provide important reference for keyword selection.Understanding Target AudiencesFirst, businesses need to clarify who their target audience is, what their needs and interests are. By collecting a large amount of user data through surveys, social media interactions, and user interviews, businesses can better understand user search habits, thereby selecting keywords that better meet user needs.Analyzing Competitors' Keyword StrategiesSecondly, analyzing competitors' keyword strategies is also an important part of market research. Businesses can use SEO tools (such as SEMrush, Ahrefs, etc.) to view competitors' website traffic sources, keyword rankings, and other information. By comparison, businesses can discover keywords that competitors have not covered, thus finding potential spot unclassified keywords.2. Use of Keyword ToolsUsing keyword research tools can help businesses discover potential unclassified keywords. Tools such as Google Keyword Planner, Ahrefs, Ubersuggest, etc., can provide data on keyword search volume, competitiveness, helping businesses make wise choices.Google Keyword PlannerGoogle Keyword Planner is a free keyword research tool that allows users to enter related words or phrases to obtain data on search volume and competitiveness of related keywords. The tool can also provide historical data on keywords, helping businesses understand keyword trends.AhrefsAhrefs is a powerful SEO tool that provides not only keyword research but also competitor analysis, backlink analysis, and other functions. Businesses can use Ahrefs to find unclassified keywords and analyze their potential traffic.3. Analyze Search Volume and Competitiveness of KeywordsEvaluating the search volume and competitiveness of keywords is an important step in selecting keywords. Keywords with high search volume often indicate greater traffic potential, while keywords with low competitiveness are easier to rank.How to Evaluate Keyword Search VolumeBusinesses can view the average monthly search volume of keywords through keyword tools. Generally, the higher the search volume, the more popular the keyword, but it also means more competition. Therefore, when selecting keywords, businesses should consider both search volume and competitiveness.Analysis Method of CompetitivenessCompetitiveness is usually assessed by analyzing the number of websites ranking in the top few positions in search engines. Businesses can view indicators such as domain authority, number of backlinks of these websites to judge the competitiveness of the keyword. For keywords with low competitiveness, businesses can more easily rank and attract more traffic.4. Consider the Relevance of KeywordsChoosing keywords that are relevant to the business is crucial. Keywords with high relevance can not only attract target audiences but also improve conversion rates. When selecting keywords, businesses should ensure that the chosen keywords are closely related to their products or services.Relevance of Keywords to the BusinessBusinesses can judge the relevance of keywords by analyzing user search intent. For example, if a business sells fitness equipment, keywords related to "buying fitness equipment" are highly relevant, while keywords related to "fitness recipes" may be less relevant.Select Keywords Closely Related to Products or ServicesWhen selecting keywords, businesses can also consider using long-tail keywords. Long-tail keywords are usually composed of multiple words, although the search volume is low, the competitiveness is relatively low, and they are more targeted. For example, "fitness equipment suitable for home use" is a long-tail keyword that can better attract specific target audiences.Part Three: Optimizing the Use of Keywords1. Keyword PlacementProperly placing keywords is key to optimizing SEO. In website content, keywords should be naturally integrated into titles, descriptions, and body text to improve search engine friendliness.Proper Placement in Website ContentWhen writing website content, businesses should ensure that keywords appear naturally. The keyword density should not be too high to avoid being identified as keyword stuffing by search engines. Generally, a keyword density of 1% to 2% is appropriate.How to Use Keywords in Titles, Descriptions, and Body TextUsing keywords in titles can increase the click-through rate of a page, while using keywords in descriptions can help improve search engine rankings. In the body text, the use of keywords should be natural and smooth, avoiding forced insertion.2. Content CreationCreating high-quality content based on selected keywords is an effective way to attract users. Content should be natural and avoid keyword stuffing.Criteria for High-Quality ContentHigh-quality content should have the following characteristics: rich information, clear structure, concise language, and easy to read. By providing practical solutions, industry insights, and user cases, businesses can improve the quality of content.Maintaining the Natural Flow of ContentWhen writing content, businesses should focus on the overall logic and coherence of the content. The use of keywords should be closely related to the theme of the content, avoiding forced insertion. Additionally, using synonyms and related words can enrich the expression of content.3. Monitoring and AdjustingRegularly monitoring the performance of keywords, analyzing data feedback, and adjusting keyword strategies in a timely manner to ensure continuous traffic growth.Regular Monitoring of Keyword PerformanceBusinesses can use tools such as Google Analytics, Ahrefs, etc., to regularly monitor the performance of keywords. By analyzing data such as click-through rates, conversion rates of keywords, businesses can understand which keywords perform well and which keywords need adjustment.Adjusting Keyword Strategies Based on Data FeedbackBased on monitoring results, businesses can adjust keyword strategies in a timely manner. For example, if the performance of a keyword is poor, businesses can consider changing the keyword or optimizing related content to improve its ranking and traffic.Part Four: Case Studies1. Success StoriesAnalyzing successful businesses that have chosen spot unclassified keywords can provide insights for other businesses. These businesses typically excel in market research, keyword selection, and content creation.Case Study One: A Fitness Equipment CompanyA fitness equipment company discovered through market research that many users who search for "home fitness equipment" are actually more interested in "fitness equipment suitable for small spaces." Therefore, the company chose this spot unclassified keyword and optimized it in website content. As a result, the ranking of this keyword quickly rose, bringing in a large number of potential customers.Case Study Two: An Online Education PlatformAn online education platform, when analyzing competitors' keyword strategies, found that the keyword "online programming courses" was highly competitive. They then chose the long-tail keyword "online programming courses for beginners" and created related high-quality content. As a result, the platform's traffic significantly increased, and the conversion rate also improved.2. Failure CasesDiscussing failure cases of improper keyword selection can help businesses realize the importance of keyword selection and summarize improvement suggestions.Case Study One: An E-commerce WebsiteAn e-commerce website, in pursuit of popular keywords when selecting keywords, ultimately led to slow website traffic growth. Although their product quality was high, due to intense competition, the website's ranking could not improve. After analysis, they realized they should focus on unclassified keywords to gain better exposure in specific areas.Case Study Two: A Travel CompanyA travel company, when selecting keywords, did not consider the relevance of keywords, resulting in low website traffic. Although they chose the popular keyword "travel," due to lack of specificity, the users attracted did not match their target audience. Eventually, they adjusted their keyword strategy, choosing the more relevant keyword "family-friendly travel," resulting in a significant increase in traffic and conversion rates.ConclusionChoosing spot unclassified keywords is an important part of digital marketing. Through market research, the use of keyword tools, analysis of search volume and competitiveness, and content optimization, businesses can effectively increase their online visibility. Continuous monitoring and adjustment are also key to success. It is hoped that this article can provide valuable guidance and inspiration for readers in keyword selection.AppendixRecommended Tools and Resources- Google Keyword Planner- Ahrefs- SEMrush- UbersuggestBooks and Articles for Further Reading- "The Art of SEO: A Practical Guide to Search Engine Optimization"- "Content Marketing: The Art and Science of Guiding Customers"