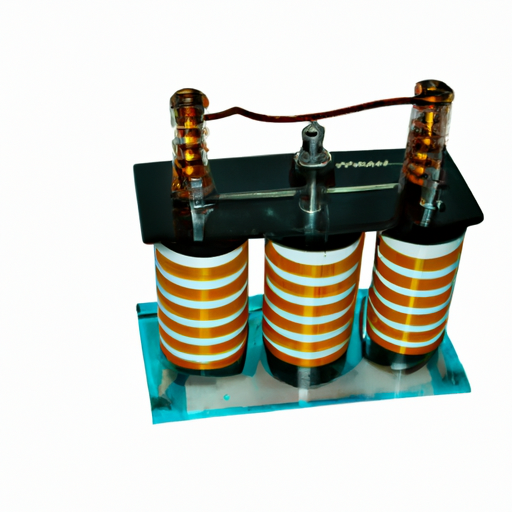

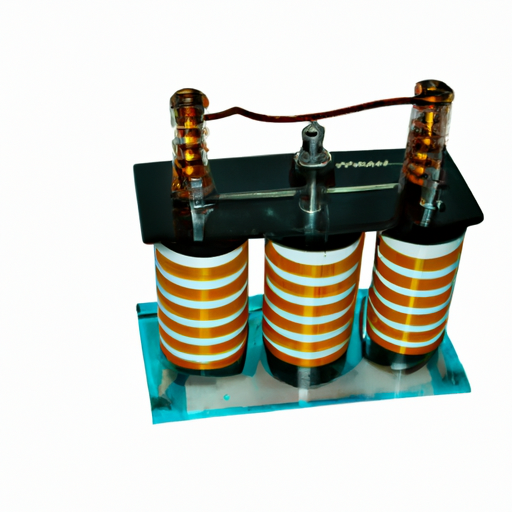

The pulse transformer industry is experiencing several key trends that are shaping the future of this important component in electronic devices. As technology continues to advance, the demand for pulse transformers is increasing, driven by the growing need for high-performance and reliable power conversion and signal isolation in a wide range of applications. In this article, we will explore some of the key trends in the pulse transformer industry and their implications for manufacturers, suppliers, and end-users.

One of the most significant trends in the pulse transformer industry is the increasing demand for high-frequency pulse transformers. As electronic devices become more complex and operate at higher frequencies, the need for pulse transformers that can handle these higher frequencies is growing. High-frequency pulse transformers are essential for applications such as power supplies, data communication, and medical devices, where fast and accurate signal transmission is critical.

Manufacturers are responding to this trend by developing new materials and designs that can support higher frequencies while maintaining high efficiency and reliability. For example, the use of advanced materials such as ferrite cores and high-frequency windings can help improve the performance of pulse transformers at higher frequencies. Additionally, the development of new manufacturing techniques, such as automated winding processes and precision machining, is enabling manufacturers to produce high-frequency pulse transformers with tighter tolerances and better performance.

2. Growing demand for miniaturization and integration

Another key trend in the pulse transformer industry is the growing demand for miniaturization and integration. As electronic devices become smaller and more compact, there is a need for pulse transformers that can be integrated into smaller spaces without sacrificing performance. Miniaturized pulse transformers are essential for applications such as mobile devices, wearables, and IoT devices, where space is limited and power efficiency is critical.

Manufacturers are responding to this trend by developing compact and lightweight pulse transformers that can be easily integrated into small electronic devices. By using advanced materials and manufacturing techniques, manufacturers are able to produce pulse transformers that are smaller, yet still deliver high performance and reliability. Additionally, the integration of multiple functions, such as signal isolation and power conversion, into a single pulse transformer is becoming more common, allowing for further miniaturization and simplification of electronic designs.

3. Focus on energy efficiency and sustainability

With the increasing emphasis on energy efficiency and sustainability, there is a growing focus on developing pulse transformers that are more energy-efficient and environmentally friendly. Pulse transformers play a critical role in power conversion and signal isolation, and improving their efficiency can help reduce energy consumption and minimize environmental impact. Manufacturers are exploring new materials and designs that can improve the efficiency of pulse transformers, such as using low-loss cores and windings, and optimizing the design for maximum performance.

In addition to energy efficiency, there is also a growing interest in developing pulse transformers that are more sustainable and environmentally friendly. This includes using recyclable materials, reducing the use of hazardous substances, and implementing eco-friendly manufacturing processes. By focusing on sustainability, manufacturers can not only reduce their environmental footprint but also meet the growing demand for environmentally conscious products from consumers and regulatory bodies.

4. Adoption of advanced technologies

As technology continues to advance, the pulse transformer industry is also adopting new technologies to improve performance and reliability. One of the key technologies that is being adopted is digitalization, which allows for more precise control and monitoring of pulse transformers. By integrating digital sensors and control systems into pulse transformers, manufacturers can optimize performance, diagnose issues, and improve efficiency in real-time.

Another advanced technology that is being adopted in the pulse transformer industry is additive manufacturing, also known as 3D printing. Additive manufacturing allows for the rapid prototyping and production of complex and customized pulse transformers, enabling manufacturers to quickly iterate on designs and bring new products to market faster. By leveraging additive manufacturing, manufacturers can reduce lead times, lower costs, and improve the overall quality of pulse transformers.

5. Focus on reliability and quality

In addition to performance and efficiency, there is a growing focus on reliability and quality in the pulse transformer industry. Pulse transformers are critical components in electronic devices, and any failure or malfunction can have serious consequences. Manufacturers are investing in quality control processes, testing procedures, and certifications to ensure that pulse transformers meet the highest standards of reliability and performance.

By implementing rigorous quality control measures, manufacturers can identify and address potential issues early in the production process, reducing the risk of defects and failures in the field. Additionally, manufacturers are working closely with suppliers to ensure the quality of materials and components used in pulse transformers, as well as collaborating with customers to understand their specific requirements and ensure that pulse transformers meet their performance and reliability expectations.

In conclusion, the pulse transformer industry is experiencing several key trends that are shaping the future of this important component in electronic devices. From the increasing demand for high-frequency pulse transformers to the focus on miniaturization, energy efficiency, and sustainability, manufacturers are adapting to meet the evolving needs of the market. By embracing advanced technologies, focusing on reliability and quality, and collaborating with suppliers and customers, manufacturers can continue to innovate and drive the growth of the pulse transformer industry in the years to come.

The pulse transformer industry is experiencing several key trends that are shaping the future of this important component in electronic devices. As technology continues to advance, the demand for pulse transformers is increasing, driven by the growing need for high-performance and reliable power conversion and signal isolation in a wide range of applications. In this article, we will explore some of the key trends in the pulse transformer industry and their implications for manufacturers, suppliers, and end-users.

One of the most significant trends in the pulse transformer industry is the increasing demand for high-frequency pulse transformers. As electronic devices become more complex and operate at higher frequencies, the need for pulse transformers that can handle these higher frequencies is growing. High-frequency pulse transformers are essential for applications such as power supplies, data communication, and medical devices, where fast and accurate signal transmission is critical.

Manufacturers are responding to this trend by developing new materials and designs that can support higher frequencies while maintaining high efficiency and reliability. For example, the use of advanced materials such as ferrite cores and high-frequency windings can help improve the performance of pulse transformers at higher frequencies. Additionally, the development of new manufacturing techniques, such as automated winding processes and precision machining, is enabling manufacturers to produce high-frequency pulse transformers with tighter tolerances and better performance.

2. Growing demand for miniaturization and integration

Another key trend in the pulse transformer industry is the growing demand for miniaturization and integration. As electronic devices become smaller and more compact, there is a need for pulse transformers that can be integrated into smaller spaces without sacrificing performance. Miniaturized pulse transformers are essential for applications such as mobile devices, wearables, and IoT devices, where space is limited and power efficiency is critical.

Manufacturers are responding to this trend by developing compact and lightweight pulse transformers that can be easily integrated into small electronic devices. By using advanced materials and manufacturing techniques, manufacturers are able to produce pulse transformers that are smaller, yet still deliver high performance and reliability. Additionally, the integration of multiple functions, such as signal isolation and power conversion, into a single pulse transformer is becoming more common, allowing for further miniaturization and simplification of electronic designs.

3. Focus on energy efficiency and sustainability

With the increasing emphasis on energy efficiency and sustainability, there is a growing focus on developing pulse transformers that are more energy-efficient and environmentally friendly. Pulse transformers play a critical role in power conversion and signal isolation, and improving their efficiency can help reduce energy consumption and minimize environmental impact. Manufacturers are exploring new materials and designs that can improve the efficiency of pulse transformers, such as using low-loss cores and windings, and optimizing the design for maximum performance.

In addition to energy efficiency, there is also a growing interest in developing pulse transformers that are more sustainable and environmentally friendly. This includes using recyclable materials, reducing the use of hazardous substances, and implementing eco-friendly manufacturing processes. By focusing on sustainability, manufacturers can not only reduce their environmental footprint but also meet the growing demand for environmentally conscious products from consumers and regulatory bodies.

4. Adoption of advanced technologies

As technology continues to advance, the pulse transformer industry is also adopting new technologies to improve performance and reliability. One of the key technologies that is being adopted is digitalization, which allows for more precise control and monitoring of pulse transformers. By integrating digital sensors and control systems into pulse transformers, manufacturers can optimize performance, diagnose issues, and improve efficiency in real-time.

Another advanced technology that is being adopted in the pulse transformer industry is additive manufacturing, also known as 3D printing. Additive manufacturing allows for the rapid prototyping and production of complex and customized pulse transformers, enabling manufacturers to quickly iterate on designs and bring new products to market faster. By leveraging additive manufacturing, manufacturers can reduce lead times, lower costs, and improve the overall quality of pulse transformers.

5. Focus on reliability and quality

In addition to performance and efficiency, there is a growing focus on reliability and quality in the pulse transformer industry. Pulse transformers are critical components in electronic devices, and any failure or malfunction can have serious consequences. Manufacturers are investing in quality control processes, testing procedures, and certifications to ensure that pulse transformers meet the highest standards of reliability and performance.

By implementing rigorous quality control measures, manufacturers can identify and address potential issues early in the production process, reducing the risk of defects and failures in the field. Additionally, manufacturers are working closely with suppliers to ensure the quality of materials and components used in pulse transformers, as well as collaborating with customers to understand their specific requirements and ensure that pulse transformers meet their performance and reliability expectations.

In conclusion, the pulse transformer industry is experiencing several key trends that are shaping the future of this important component in electronic devices. From the increasing demand for high-frequency pulse transformers to the focus on miniaturization, energy efficiency, and sustainability, manufacturers are adapting to meet the evolving needs of the market. By embracing advanced technologies, focusing on reliability and quality, and collaborating with suppliers and customers, manufacturers can continue to innovate and drive the growth of the pulse transformer industry in the years to come.